Pressure tanks

.

Receivers for refrigerants

Receivers for accumulation and storage of liquid coolants are manufactured in 4 series of types:

- Horizontal vessels ZH; capacity 5-40 dm3

- Vertical vessels ZV; capacity 5-40 dm3

- Horizontal vessels ZHR; capacity 61-2090 dm3

- Vertical vessels ZVR; capacity 61-927 dm3

.

Air receivers

We are producing air receivers used in following installations:

- Damping of pressure pulsation in paper-pulp transporting pipelines

- Ships' engines start-up systems

- Systems of pneumatic tools

.

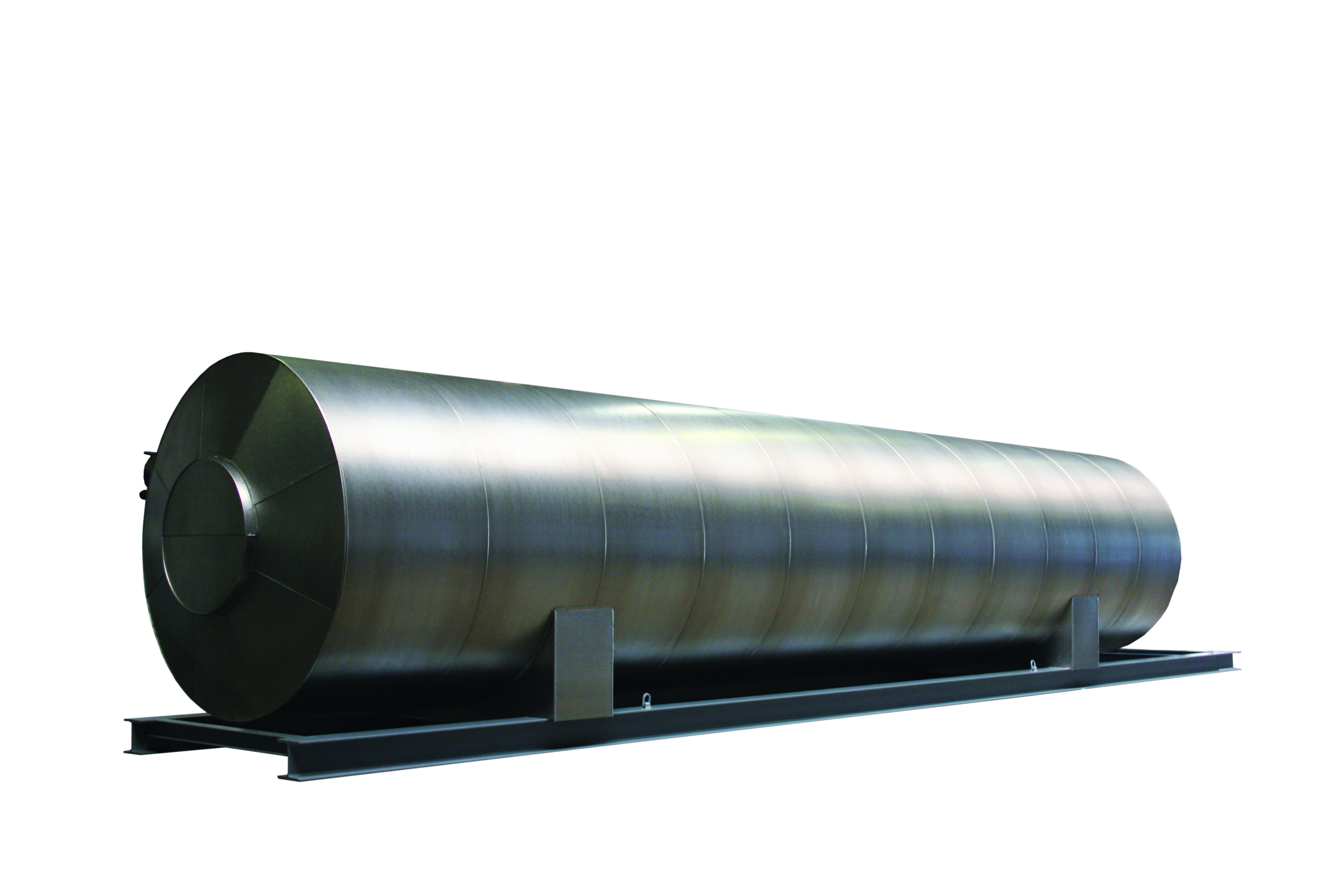

Pressure vessels for CO2

Vessels for storage of liquefied carbon dioxide (design temperature -40oC, designed pressure:: 24,5 bar) for marine fire fighting systems.

Volume: from 6m3 to 60m3

Material: low-temperature steel

Isolation: polyurethane foam covered with aluminum sheet

Certification: DNV-GL, ABS, LRS, RINA, BV, NKK, CCS

.

Tanks for water

Water tanks manufactured in PBUCH SA are designed for working in a different technological systems:

- Vessels for chilled water for HVAC systems,

- Vessels for boiler water for heating systems

- Vessels for domestic systems for hydrophore units

.

Hydrophore units

Hydrophore units are designed for preparing, water treatment and pumping drinking water in fresh water systems on ships.

Such units are made from following components set on a skid:

- Hydrophore tank

- Calorifier

- Set of pumps

- Filtration modul including: carbon filter, a UV sterilizer and a chlorinator

- Control system and electric switchgear

- Valves and piping

.

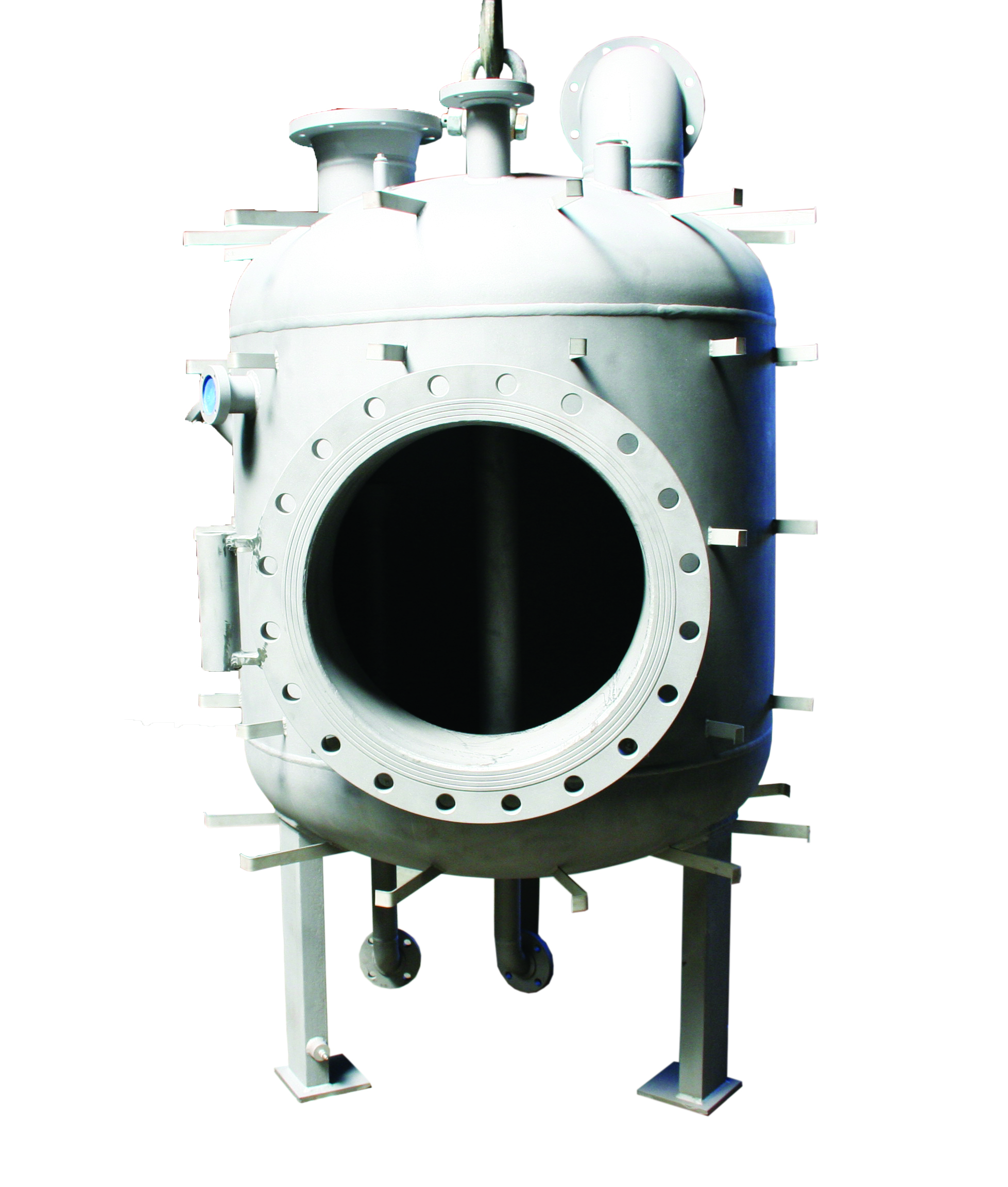

Ammonia Separator

We offer wide variety of vessels and liquid separators for ammonia with capacity from a few hundreds up to 60 000l/hour

NH3 from the refrigeration plant can be accumulated in storage tank to prevent losses of ammonia during refrigeration system stopage or renovation.

Shell material: P355NL1 steel compatible with PN-EN 10028-3 or steel P265GH compatible with PN-EN 10028-2

Design pressure: 20 bar

Test pressure: 30 bar

Min/.max temperature: -40/+50OC

Medium: R717

Customised drawing

Certification: UDT , PED according to 2014/68/EU, Marine Classification Bodies.

.

Separators

Separator of hydrocarbon-water-vapor mixture – a pressure vessel used for separating drilling fluids from the oil wells on separate ingredients: vapor, water and oil. Manufactured according to “Offshore standard: DNV-OS-D101 - Marine and Machinery Systems and Equipment”.

Separator is equipped with manhole, baffles, connections and laser and magnetostrictive level sensor.

Level sensor was used for the high-accuracy, continuous level measurement of liquids, based on determining the position of a magnetic float according to the magnetostrictive measuring principle.

Separator was designed for working temperature in range between -7oC and 170oC, and because of it’s localization on upper deck of Martin Linge FSI it has been isolated and protected with shell made of steel plate.

.

Tanks for Bulk Handling Systems

Bulk material tanks

According to requirements PBUCH is producing pressure tanks for various bulk materials:

- Cement

- Barit/bentonite

- Extinguishing powders

Such vessels are used in PSV/OSV (Platform/ Offshore Supply Vessel) Bulk Handling Systems for storage and transport of bulk materials needed during a process of crude oil extracting.

.

Tank modules

Following project requirements of our clients PBUCH offers engineering and production of tank modules built on a frame and equipped with control system.

Skid includes:

Pressure vessels, cyclone, dust collector, pipelines and mnifolds, valves.

The DCP tank modules are designed to filter out the usable powder from the air.

Technical data:

Length: 2700 mm

Width: 1650 mm

Height: 4037 mm

Weight: 5500 kg

Working pressure: 6 bars

Control system

.

Loading stations

Loading stations are a special system for transporting dry and liquid bulk cargoes needed on drilling platforms, such as cement used to plug boreholes and barite to balance pressure in wells. In addition, this system is also used to transport waste generated as a result of drilling.

Large size tanks

.

Bulk tanks with a 6m diameter

Special purpose tank, used for storage of bulk materials on off-shore vessel built in Crist Shipyard in Gdynia.

Parameters:

Volume: 116 m3

Desing pressure: 5,8 bar

Diameter: 6000 mm

Height: 5350 mm