Marine refrigeration and air-conditioning equipment

.

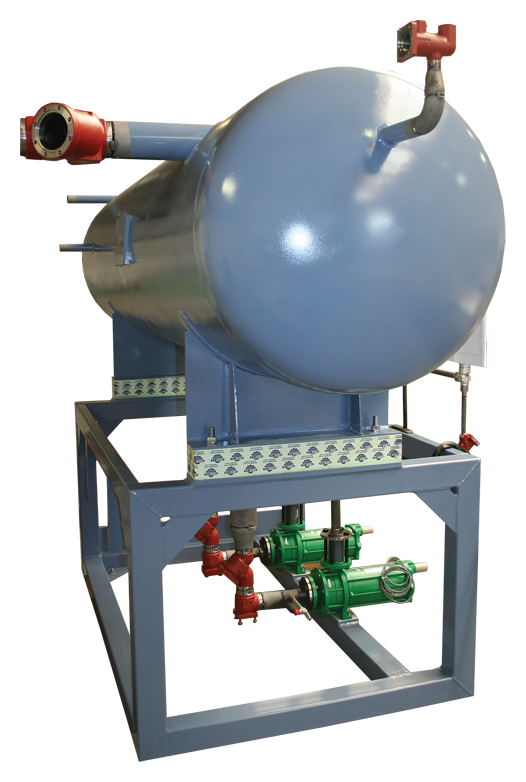

Marine chiller units WCH type

Chillers (water cooling units) are compact units adapted for fresh water or brine condenser cooling. Depending on needs, it is possible to offer dedicated, customised version of the chiller, made of special materials (eg low-magnetic version), special protection (eg shock absorbers), non-standard power supply, control, loads or construction.

Chillers consist of the following components:

Compressor

Depending on the efficiency and needs, it is possible to produce aggregates with reciprocating compressors, screw compressors (semi-hermetic or open) or Scroll compressors.

Condenser

As a standard, we use shell and tube condensers adapted for cooling with fresh water (copper low-finned tubes), brine or sea water (low-finned copper-nickel or brass tubes). Thanks to the use of outside and inside finned tubes, the condenser obtains better heat transfer parameters and thus smaller overall dimensions.

Evaporator

It is possible to use shell-and-tube or plate evaporators. If required, the evaporator can be made of stainless steel. The evaporator's inlet and outlet temperature sensors, flow sensor and anti-freeze sensor are used to control the water flow through the evaporator.

Refrigeration circuit

Chiller unit is equipped with: shut-off valves, filter dryer, electronic expansion valves, high and low pressure gauges, pressure transmitters, solenoid valve and safety valves.

Microprocessor controll

The controller has, among others the following functions:

- Maintaining the chilled water temperature at the outlet of evaporator

- Anti-freeze protection

- Compressors’ control and timer for their work

- Regulation of the efficiency level

- Signals from a remote control system

- Alerts about exceeding of set parameters

.

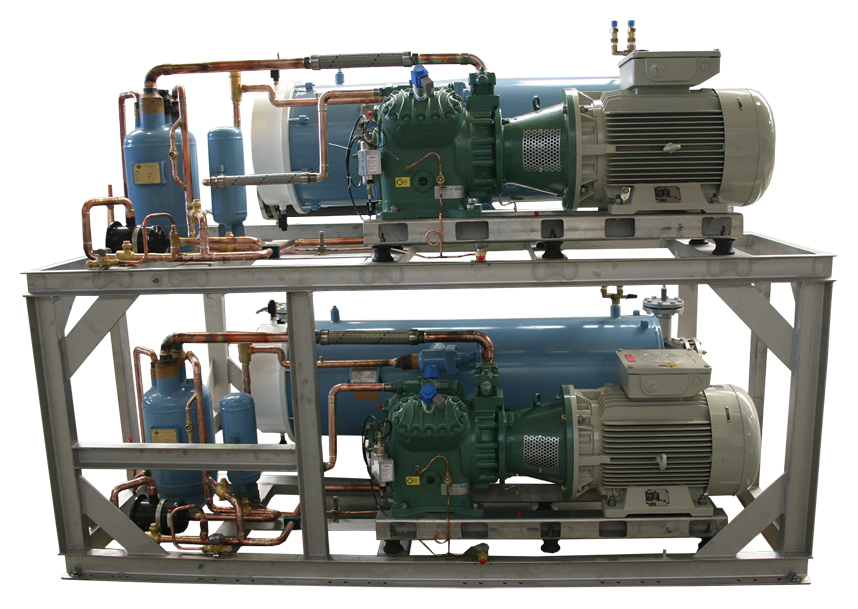

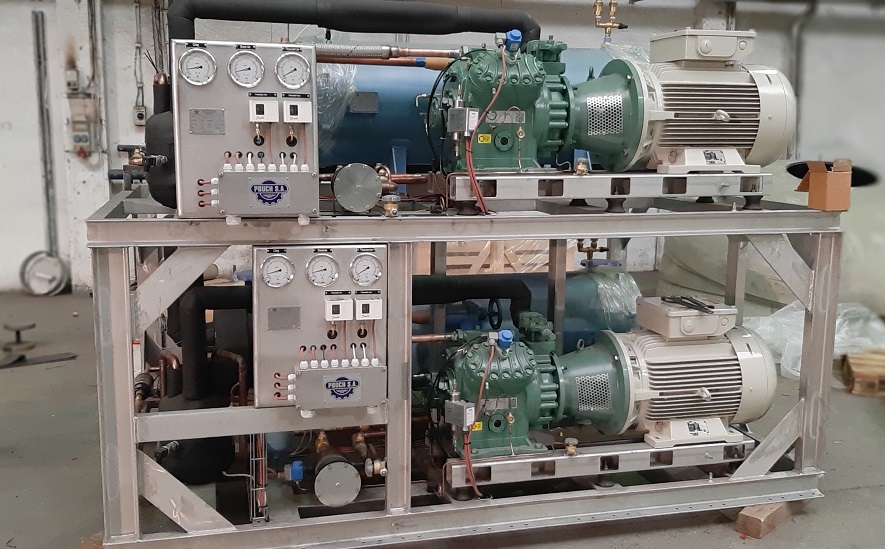

Condensing and compressor units

WCU condensing units, are designed to work in air conditioning systems with air-handling unit's cooling section and in refrigeration systems of cold and freezing stores.

The aggregate in the standard version includes:

- piston or screw compressor adapted to work in a ship environment

- shell and tube condenser cooled with fresh or sea water

- control board with automatic control and protection system of the unit,

- control and safety valves

and can be equipped optionally with:

- oil separator

- oil level control

- discharge temperature sensor

- oil pressure switch

- capacity control

- special protection for compressor's motor

- frequency inverter

AP condensing units are equipped with an air-cooled condenser.

The CU compressor units are designed for refrigeration systems with a remote condenser.

They are made of compressor, oil separator, board with control and safety instruments and shut-off valves.

For compressors in the above mentioned aggregates, additional equipment is optionally available:

- the start-up unloading,

- performance regulation

- additional compressor cooling,

- shock absorbers

.

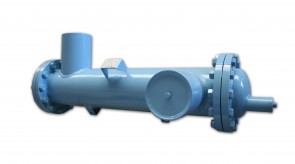

Shell and tube condensers: SPR and SPRZ type

Shell and tube condensers, SPR and SPRZ type, are designed for condensing refrigerant vapors in refrigeration units, and the SPRZ tank condensers are additionally used to store the liquid refrigerant.

The condensers consist of a body, buddle of low-finned tubes, expanded in tube sheets and water covers.

The cooling water flows in the tubes, while the cooling agent condenses in the inter-wall space on their outer surface.

Removable covers direct the flow of water on both sides of the condenser, they are equipped with inlet and outlet connectors for water. That construction allows mechanical cleaning of tubes of impurities.

Water covers are protected against corrosion by polyamide layer, which is characterized by good tightness, durability and abrasion resistance as well as low coefficient of friction in relation to water.

Thanks to covering the water cover with polyamide, effective protection against electrolytic corrosion is obtained, which can occur at the contact of various metals in the sea water environment.

In the reservoir version of the condensers (type SPRZ), are designed to condense and storage refrigerants.

In the lower part of the shell of SPRZ type are located two sight glasses allowing observation of the level of the refrigerant inside the condenser.

Condensers can ba built of low finned tubes made of copper (fresh water cooled), cupronickel or brass (sea water cooled).

Condensers are constructed and approved according to requirements of Classification Bodies: DNV / GL, LRS, BV, RMRS, RINA, ABS, PRS and also UDT or TUV.

.

Shell and tube evaporators PSGR type

Shell and tube evaporators (dry expansion type) with the evaporating of the medium inside the tubes are designed for cooling water, technological brine or glycol solutions used in air-conditioning plants.

.

Refrigerant receivers

We offer various receivers for accumulation and storage of HFC refrigerants in cooling plant:

- vertical receivers (ZV, ZVR)

- horizontal receivers (ZH, ZHR).

Receivers can be equipped optionally with level indicator, shut-off and relief valves.

Besides we offer receivers for other refrigerants: ammonia, CO2 and also for accumulation of water or brine in the indirect system.

.

Marine air-conditioners type MAC

MAC compact air conditioners are adapted to work in wheelhouses and other rooms on passenger ships, commercial vessels, platforms.

- Cooling capacity: 6-43kW

- Power supply 3x400V / 50Hz or 3x440V / 60Hz

- Equipment:

- Compressor - hermetic reciprocating compressor equipped with a heater;

- Shell and tube condenser with a tube insert made of Cu-Ni tubes, designed for cooling with seawater or with a Cu tubes intended for cooling with fresh water

- Air cooler - copper coil with aluminum fins for use in ship conditions

- EU2 filter

- Fan - centrifugal fan with an electric motor with IP55 protection.

- Control - the temperature is controlled by a thermostat. It is possible to choose manual or automatic operation mode. The control panel has IP55 and automatic circuit breakers. The compressor is equipped with high and low pressure switches, a liquid-side solenoid valve, filter drier, liquid side sight glasses and manometers.

- Optional equipment:

- air chamber

- silencer at the fresh air inlet

- connection for the ventilation duct of the air outlet from the air conditioner

- flexible connection for fresh air inlet and outlet

- stainless steel housing

- coil with copper fins

- electric heating

- automatic seawater valves

- refrigerant

- air-cooled condenser

Refrigeration equipment for industial applications

.

Industrial refrigeration

We offer the following services for industrial plants:

- recovery of technological heat from machines and devices,

- designing of installations and devices: refrigeration and air conditioning,

- delivery and assembly of heat exchangers and chillers,

- comprehensive repairs of chillers and heat exchangers

- service of refrigeration systems,

- periodic inspections of refrigeration units,