On 03/07/2020, Przedsiębiorstwo Budowy Urządzeń Chłodniczych S.A. was transformed into CLIMAREM Sp. z o.o.

On that day, the transformation of the company was entered into the register of entrepreneurs of the National Court Register, under the number: KRS 0000848934.

Changing the legal form, and consequently the name, does not affect the continued operation of the same entity. Pursuant to the Code of Commercial Companies CLIMAREM Sp. z o.o. is the legal successor of the transformed company (general succession).

PRODUCTION OFFER

Manufacturing, repair, assemble and service of the following equipment:

We also offer installation and repair services for refrigeration, HVAC systems.

Application range

We provide products and services for the following industries:

From a concept through the engineering to prototype

PBUCH makes every effort to expand the production offer and adapt products to the individual, technological and market requirements of our client. We provide professional design services and product certification in accordance with the requirements of classification bodies as well as special standards.

All products can be obtained under approval by all major inspection authorities and standards: EN 13445, TEMA, Pressure directive: 2014/68 / UE, AD 2000, DNV / GL, LRS, ABS, BV, PRS, RINA, PRS, RMRS, BS, CCS regulations, NKK.

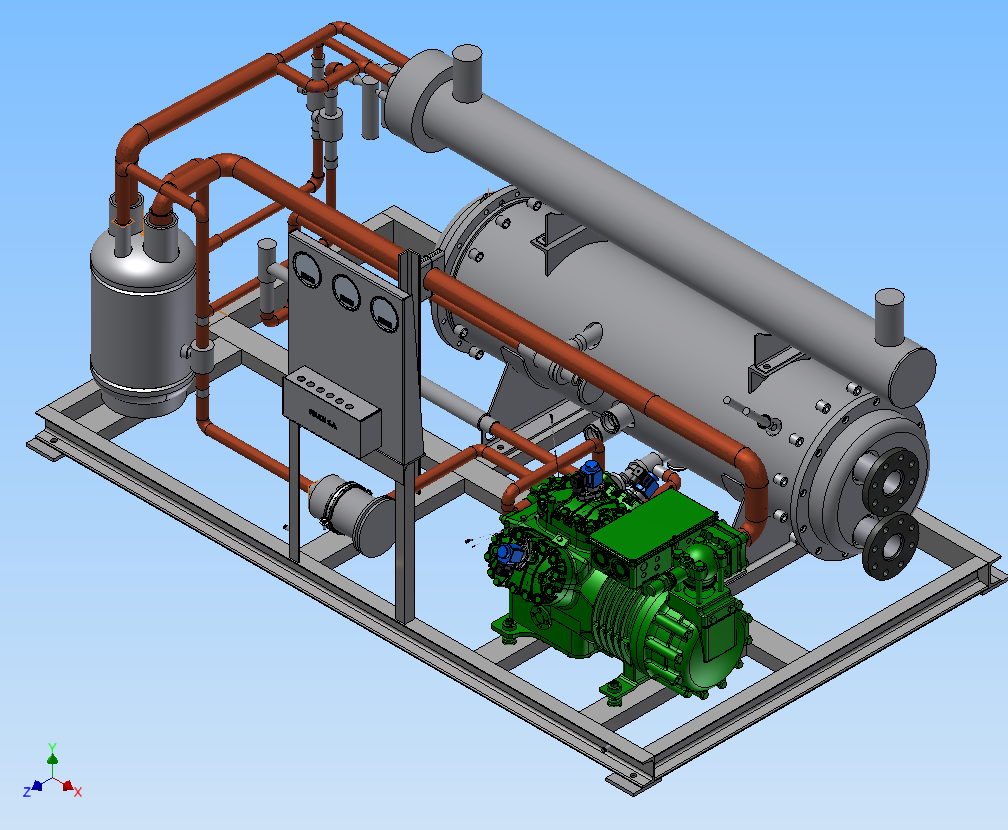

Development of an innovative, ecological refrigeration units for marine applications

We work on the research project entitled "Development of an innovative, ecological refrigeration equipment for ship applications" as part of the "INNOSHIP" Sectoral Operational Program.

The result of work on the project will be a series of refrigeration units and chillers adapted to work in marine conditions, working on the R744 and other refrigerants with a GWP factor (Global Warming Potential) below 150 with an ODP factor (Ozone Depletion Potential) equal to 0.

As part of the project, a station for testing refrigerants is being built. Station is intended for:

At the same time, we are preparing a station adapted for welding works of shell and tube heat exchangers with tubes and tube plate made of titanium.

Research and development

PBUCH takes part in research projects in cooperation with Technical Universities.

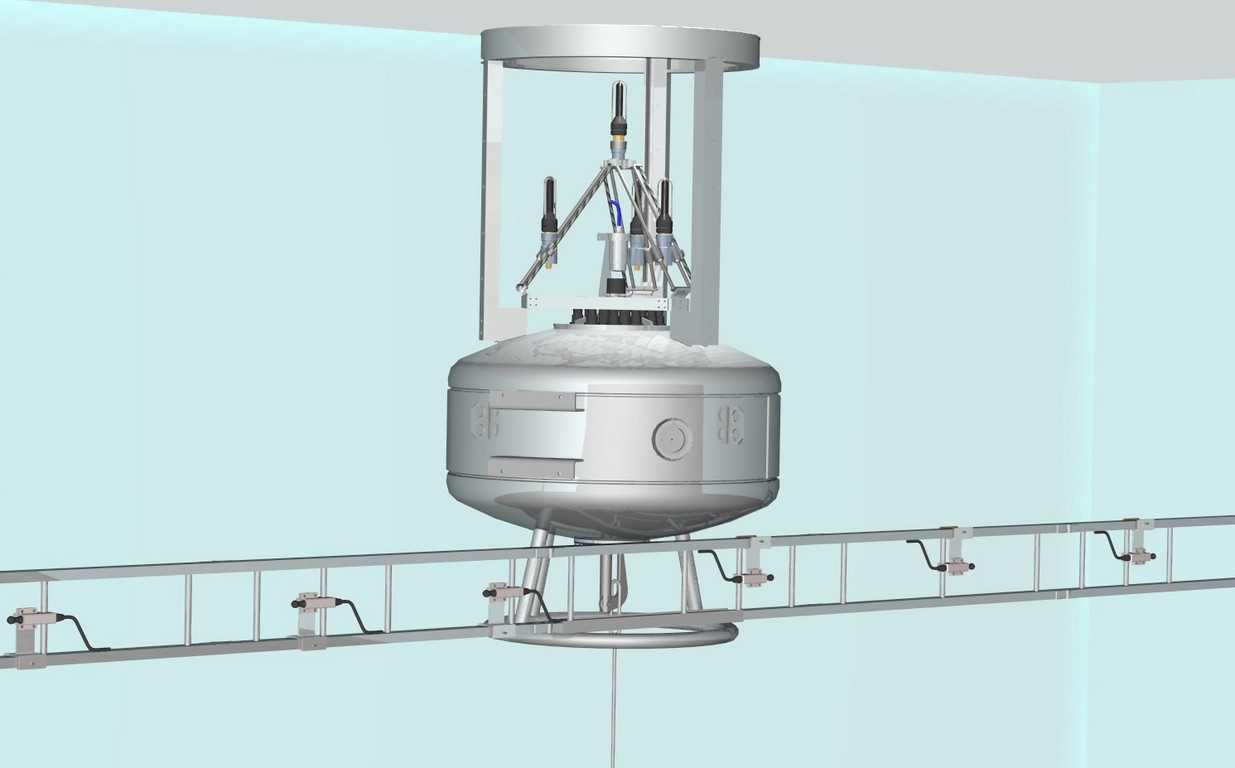

Under the Science and Industry Consortium Agreement, signed jointly with the Naval Academy and the Gdańsk University of Technology, we participated in development project entitled: "Module for physical multidimensional observation and underwater recognition”, founded by Ministry of Science and Higher Education

The main tasks of PBUCH included the production of an remote-controlled platform consisting of:

- "Autonomous underwater observation module",

- "Mobile underwater observation module",

- emergency float,

- transport platform,

- storage container.

ISO standards

We have implemented the ISO 9001: 2015 standard in the for the:

"Designing, production, assembly and repairs of: refrigeration, air-conditioning, ventilation equipment, pressure tanks and hyperbaric chambers”

Welding

Welding process in the company is under control of Welding Engineer (with the international IWE authorisation).

We currently have over 60 recognized WPQR welding technologies accepted by DNV GL, PRS, UDT and TUV, allowing for welding:

- BW and FW joint of material groups 1.1; 1.2; 5.1; 5.2; 8.1; 10.1; 22.1, by methods: 111; 121; 131; 135; 136; 141;

- BW and FW dissimilar joint, material groups 8.1 / 1.1 and 8.1 / 1.2, by methods: 135; 136; 141;

- Tubes in tube plate, TIG orbital welding, material group 1.1; 8.1, by methods 141; 142

In order to continuously improve the quality of production, we focus on automation, an example of which is TIG orbital welding of tubes in tube plates of heat exchangers and having welding machines for submerged arc welding.

We also implement the ISO 3834-2 Quality standard in welding and ISO 1090.

Materials

We specialize in the production of carbon steel, stainless steel, low temperature steel, Duplex steel and non-ferrous metals such as bronze, copper, copper-nickel, aluminum bronze, bimetals, aluminium.

Production capabilities

As part of the production of equipment, we provide the following production processes:

burning and cutting of metallurgical materials (gas and plasma)

shot blasting

grinding

rolling, bending

manual welding and with welding machine

drilling

surface protection (painting, polyamide coating, resin coating, passivation, separation and other)

All processes are subject to Quality Control in terms of material identification and character transfer

non-destructive testing: VT, PT, MT, UT, RT, HT, destructive tests, pressure tests, leak tests,

quality of welds, condition of paint coatings, anti-corrosion protection, insulation and other QC requirements.

We make devices and tanks with maximum dimensions:

length: 25m

width: 6m

height: 10m

Maximum pressure: 400 bar