HYPERBARIC CHAMBERS

.

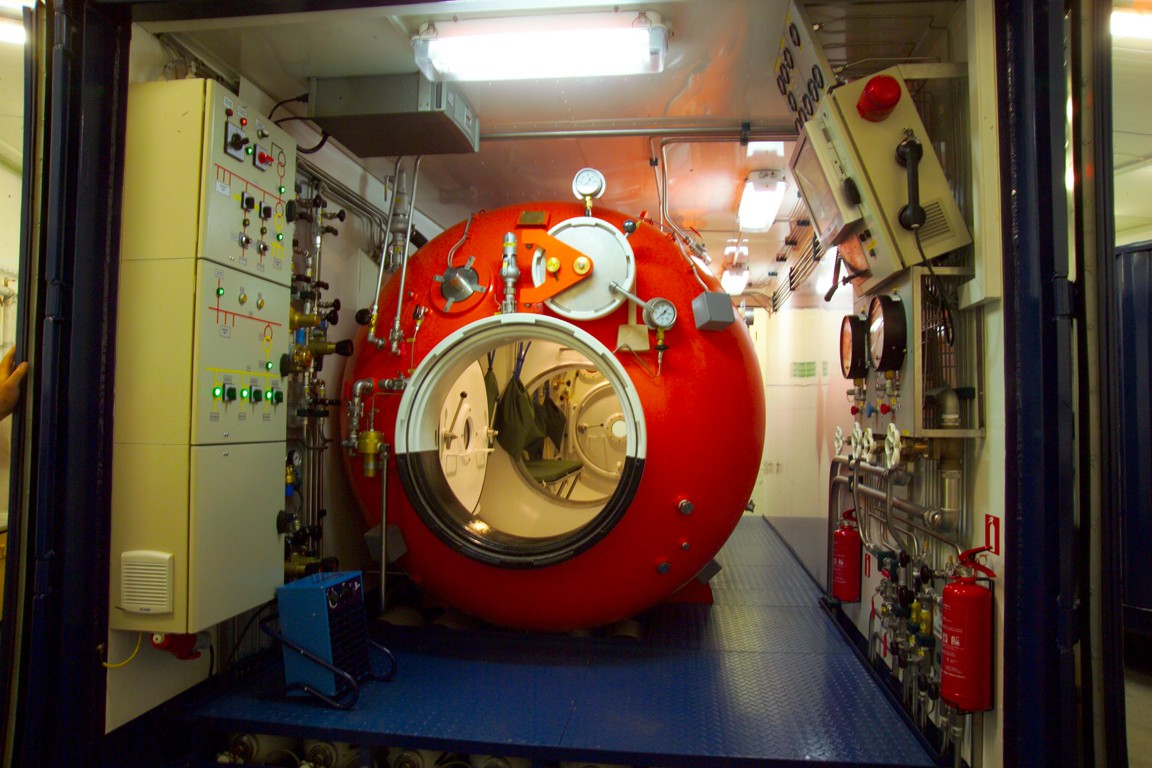

HYPERBARIC TREATMENT CHAMBER SYSTEM

The Containerized Rescue and Hyperbaric Treatment Chamber System (Decompression Chamber), manufactured by PBUCH S.A., consists of a two-compartment pressure chamber complete with equipment in a specially adapted, 20 feet insulated container. The system is used for the treatment of ilnesses and injuries, which occur as a result of increased hydrostatic pressure and to carry out training exercises for submarine crew members and divers. The equipment was designed to hold maximum 14 people, where 10 places are located in the rescue and treatment compartment and the remaining 4 in the rescue and transfer compartment.

The equipment, being the primary medical safety element of the sea rescue systems, can be used in the following ways:

- rescue actions when administering help to the submarine crew members,

- underwater works where the depth ranges up to 100 mH2O,

- treatment of diving illnesses and administration of hyperbaric oxygen therapy,

- carrying out specialist examinations and medical procedures,

- carrying out pressure training exercises,

- carrying out other pressure procedures where a human finds himself in the conditions of increased pressure.

.

Primary technical data:

- size of the container (length x width x height): 6050x2440x2590mm

- power supply: 380-440V/32A/50Hz (60Hz)

- system with container - total mass: ~ 9800 [kg]

- chamber type: two-compartment

- chamber length (total): 4947 [mm]

- internal chamber diameter: 1800 [mm]

- treatment compartment volume: 7,0 [m3]

- transfer compartment volume: 4,0 [m3]

- operating pressure: 1,0 [MPa]

- number of seats: 14 seated (or 2 lying down and 6 seated)

- diameter of transport chamber terminal: 830 [mm] flange according to AdivP-1 STANG 1079

- breathing gas type: air, oxygen or breathing gas mixtures

- breathing gas reserve: 120 [Nm3] -air; 80 [Nm3] - oxygen

- transport lock number – 2 (one lock for every compartment)

- number of portholes - 11

.

Breathing gases

The system is adapted to use the following breathing gases: air, oxygen and breathing gas mixtures, maintains the required partial pressure of the breathing gas elements and guarantees their constant control in the atmosphere of the chamber.

The storage areas for the gases are located between the chamber and the floor of the container, where 20 bottles (each with a 50 dm3 water volume capacity) are located.

The gas installation is used to store breathing gases, to send them through to the chamber, to take them away from the chamber, to carry out pressure gauging of the breathing gases and to test their composition. The principal elements of the gas installation were chosen on the basis of safety and wellbeing requirements related to persons who find themselves in an environment with increased pressure. All the installation components were prepared and assembled to take into account the strict regulations regarding oxygen purity.

.

Equipment

The inside of the hyperbaric chamber is equipped with, amongst other items, 2 cots for 2 people lying down or 8 people seated and 6 fold-away seats, 4 of which are located in the transfer compartment. The chamber has 14 inhalers in total, as well as 3 carbon dioxide absorbers and 2 hyperbaric extinguishers and heaters.

The key elements of the chamber equipment are located in the front section, on the side walls of the container. These are primarily gas distribution charts, look-up control charts, a connection panel, a switch-gear center, as well as a measurement and control desk.

The container is also equipped with a lighting system – together with the emergency lights, electric heating and extinguishers. The inside of the chamber is lit with the use of LED lamps.

The compartments of the chamber are separated from each other with a pressure bulkhead, in which an access door is installed. On both ends of the chamber there are main access doors, equipped with terminals, which fulfil the requirements of the NATO standard STANAG 1079 FLANGE. The internal diameter of all the manholes is Ø750 mm, which allows for unobstructed movement.

In addition, the chamber has two transport locks (one for each compartment) and 11 portholes (2 of which have monitoring cameras installed). In both spaces, there are also diving telephones, pressure gauges and all the necessary fixtures.

.

Chamber Breathing System BIBS

The BIBS installation, being a part of the life support system, allows an individual to breathe inside the chamber in the event that breathing is not possible directly from the atmosphere of the chamber. The equipment can use breathing gases or oxygen. The installation takes away the exhaled gases to the outside of the chamber, in order to prevent the pollution of the chamber atmosphere with breathing gas mixtures.

.

Measurement system

The extensive measurement system is used to control the atmosphere parameters of the chamber compartments and it also measures pressure, temperature, humidity and the oxygen and carbon dioxide content. In addition, the system allows monitoring of other gases and harmful impurities – it uses special instruments to take gas samples directly from the chamber compartment. The measurement system has a more important role than other installations, as it controls the safety of the people who are in the chamber and allows for its correct use.

All the parameters relating to the pressure procedures that are being carried out, are displayed at the same time on a display screen, which allows the situation to be monitored in a given compartment or in both chamber compartments simultaneously. It is also possible to record this data.

.

Autonomous qualities of the system

Apart from the possibility to connect external electric power supply and breathing gas sources, there is also an option for independent operation of the system, using the equipped gases and the 12 equipped accumulators. When fully charged, they allow for an autonomous operation of the system, with no external supply, for at least 24 hours. Thanks to the chamber having a transfer compartment, there is an option of medical personnel transfer, and thanks to the fact, that every compartment has its own independent service field, it is possible to simultaneously carry out two different hyperbaric or medical decompression procedures. The standard terminals which are located on the access doors, allow for the attachment of transport chambers.

The hyperbaric systems, which are manufactured by PBUCH, is very mobile and autonomous in operation, thanks to which their potential use is extensive. Thanks to their container structure and the mass not exceeding 10 tons, they are suited for the standard land transport, as well as transport by sea or air. Hyperbaric procedures can be carried out during the transportation of the system.