Processing equipment

Columns for reduction of the VOC emission

.

KVOC columns

To reduce the emission of Volatile Organic Compounds (VOC) to the atmosphere Knutsen OAS Shipping AS has developed the KVOC® technology. This is a technology which reduces the emission of VOC from tankers during loading and transit.

VOC are the mixture of low molecular weight organic compounds in crude oil that can be released from oil and oil products during production, processing, loading, transport, unloading and storage. The incentive to reduce the VOC emission worldwide is environmental protection and cost reduction by minimizing product losses.

PBUCH produced for the KVOC system columns of diameter 2400mm and length 23,5m, being 16 bars pressure tanks.

The KVOC® technology is based on feeding the oil at deck level tangentially into the specially designed drop line. Inside the KVOC®, the oil flows at the cylinder wall leaving and open space

in the middle. The increased diameter compared to a conventional drop line reduces the velocity of the oil and therefore the drag forces of the loaded oil.

Since the drag forces of the oil is reduced, the buoyancy forces of the oil together with the open space in the middle of the column allows the gas to rise inside the column.

Columns manufactured in PBUCH were delivered on the folowing vessels: “Tordis Knutsen”, “Elisabeth Knutsen”, “Sallie Knutsen”, “Tove Knutsen”, “Jorunn Knutsen”, “Sirri Knutsen”, “Elisabeth Knutsen”.

Heat exchangers for chemical fertilizers industry

.

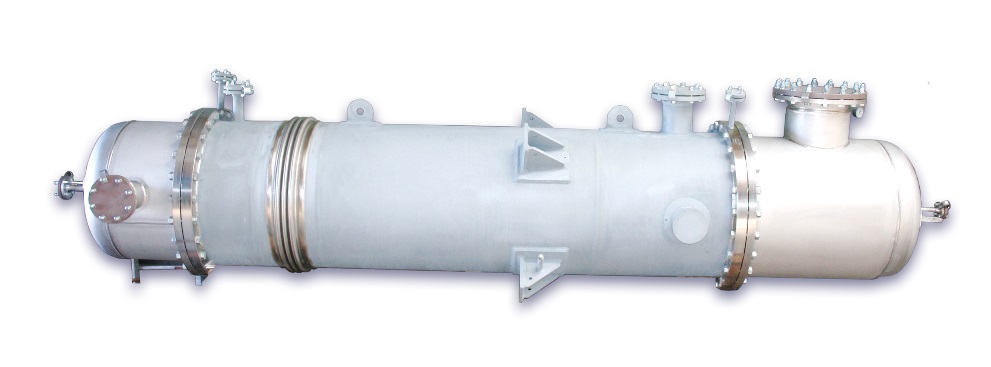

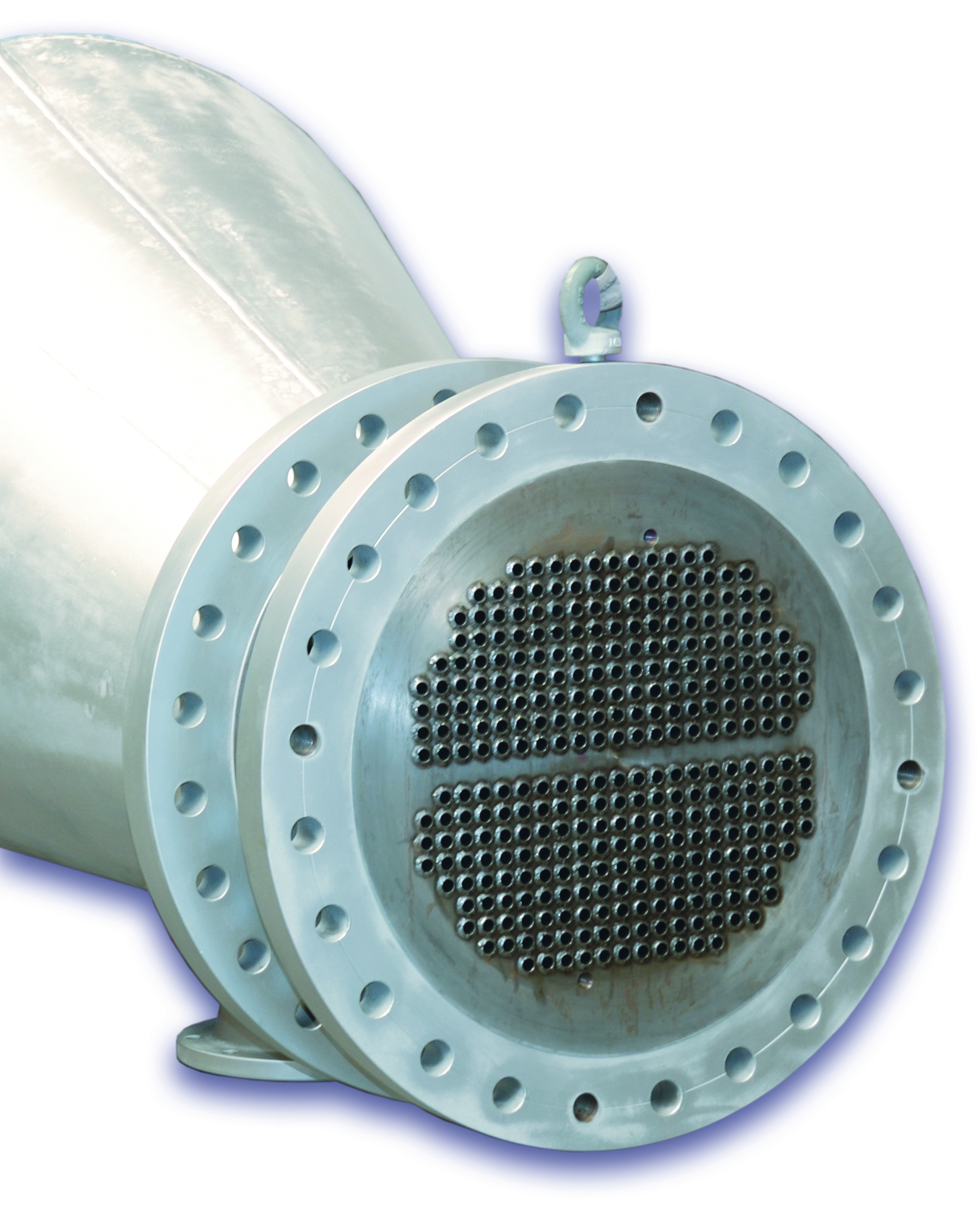

The propylene condenser (R1270)

The propylene condenser is a type AXM shell-and-tube horizontal heat exchanger used to lower the temperature of superheated propylene vapors to the saturation temperature and then to condense them.

Capacity: Q=2404 kW

Heat exchange surface – 2036 m2

Propylene flow rate efficiency: 21500 kg / h

Propylene temperature on the gas side - 85 oC and on the liquid side - 36,8 oC

Pressure – 14,4 Bar

The cooling medium is fresh water with a capacity of 60.5 kg / s.

The condenser is made of a cylindrical steel shell with a diameter of ø 1220mm with welded on both sides steel tube sheets. Tube bundle was made of CU-DHP copper. Tube plates on the water side and covers are being protected with a Cerami-Tech FG ceramic coating that protects against corrosion. A compensator was used for shell and tubes extensions.

The pressure on the shell side filled with propylene is 24 bar on the water side in tubes - 10 bar

The exchanger has been designed and certified in accordance with the Pressure Directive 2014/68 / EU, marked with the CE mark.

.

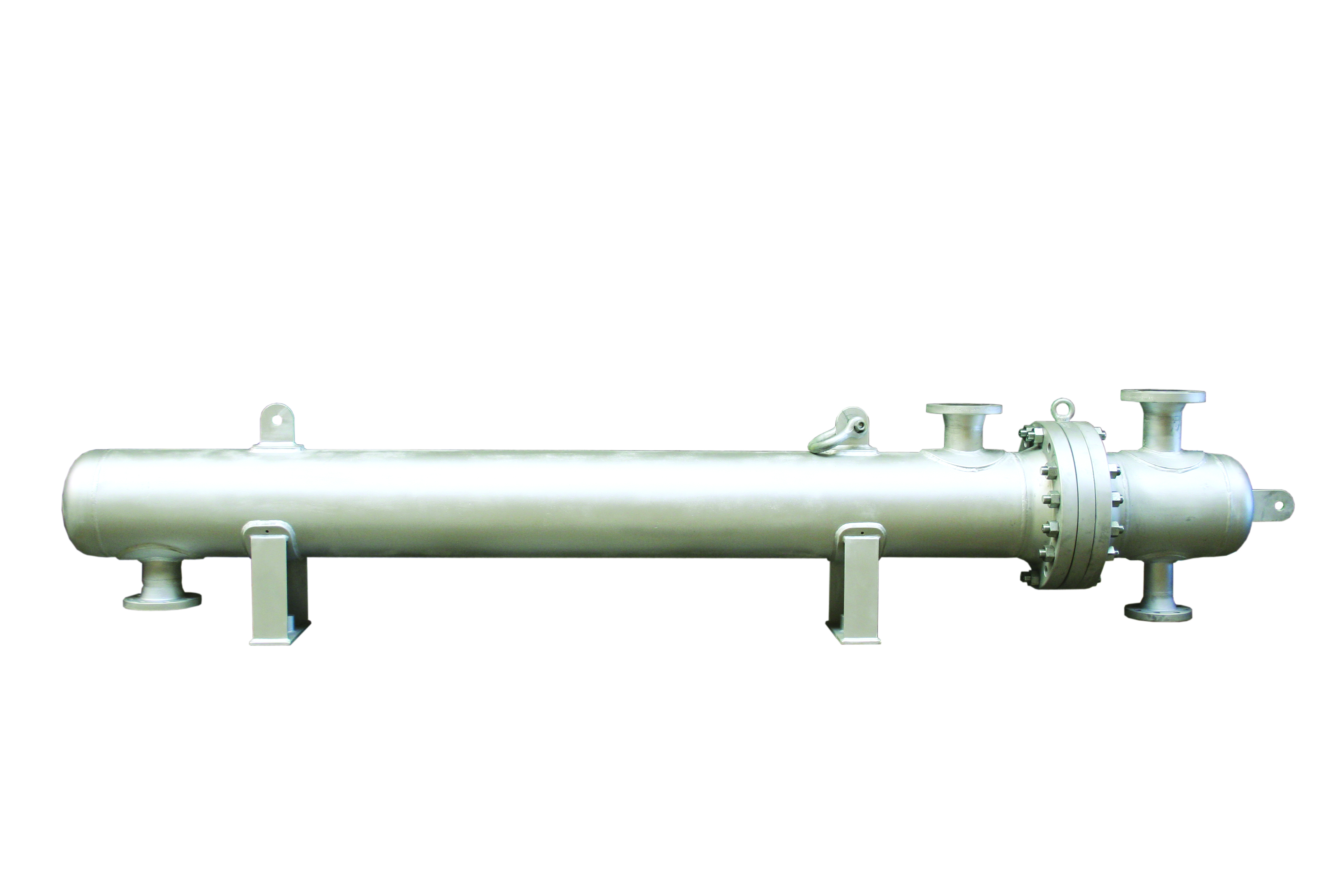

Propylene subcooler

A propylene subcooler (R1270) with a capacity of Q = 140 kW and a heat exchange surface of 52.3 m2 is a shell-and-tube horizontal BEM heat exchanger used to lower the temperature of propylene condensates.

Propylene flow rate efficiency: 21500 kg / h

Temperature of propylene: 36,8oC / 29oC

Pressure 14,4 bar

The cooling medium is fresh water with a capacity of 60.5 kg / s.

Shell diameter : ø 614mm

process tubes: CU-DHP copper.

Water-pressure test : on the shell side filled with propylene: 34.5 bar on the water side in pipes: 14.5 bar

The exchanger has been designed and certified in accordance with the Pressure Directive 2014/68 / EU, marked with the CE mark

.

Heavy oil fractions' condenser

Heavy oil fractions' condenser is a type AXM shell-and-tube heat exchanger . On the tubes' side cooling water flows with temperature parameters of 27oC / 37oC and on the shell side, toxic, flammable and explosive heavy oil fraction under pressure of 5 bar and temperature of 89oC.

Heat exchange surface – 577m2

The exchanger - both the shell (ASME SA 516 gr 60) and the tube bundle (ASTM A 516 gr 60) are made of steel intended for pressure equipment operating in an acidic environment.

.

Heat exchanger: mazut-water steam

Exchangers for the Phosphorus Fertilizer Plant - production and delivery of a heat exchanger, equipped with a compensator for a pumping and heating unit for heavy fuel oil for the needs of the Fertilizer Production Department.

Main parameters:

operation of the heat exchanger in a continuous work of the system- 1020 kg/h

oil temperature at the inlet: 60 – 70 oC

oil temperature at the outlet - 100 oC

oil pressure at the inlet – 1,1 bar

oil pressure at the outlet – 10 bar

heating steam pressure – 2,5 atm.

amount of steam – 43,5kg/h

The exchangers were designed and manufactured in accordance with the standard PN-EN 13445:2014

Materials for pressure coating in accordance with PN-EN 10204

Material for tubes, stub pipes: P235GH

Material for shell, tube sheet: P265GH

Material for supporting structure, baffles: S235JR

Technical documentation, approval by PRS Notified Body CE 1436 according to 2014/68 / EU

.

Column condenser

Used materials: X6CrNiTi18-10 (1.4541), X5CrNi18-10(1.4301), P265GH(1.0425)

Heat exchange surface: 231 m2

Medium: fluid/vapor

Test pressure: 7,1 bar

Temperature on the liquid side: 60oC

Temperature on the vapor side: 100oC.

Dimensions LxWxH: 5320mm x 1030mm x 1600mm

Weight: 5,7 tons

.

Column evaporator

Used materials: X6CrNiTi18-10 (1.4541), X5CrNi18-10(1.4301), P265GH(1.0425)

Heat exchange surface: 111 m2

Medium: fluid/vapor

Test pressure: 2,9 MPa

Temperature on the fluid side: 150oC

Temperature on the vapor side: 300oC.

Dimensions LxWxH: 5180mm x 1030mm x 1300mm

Weight: 3,9 tons

Heat exchangers for oil refinery

.

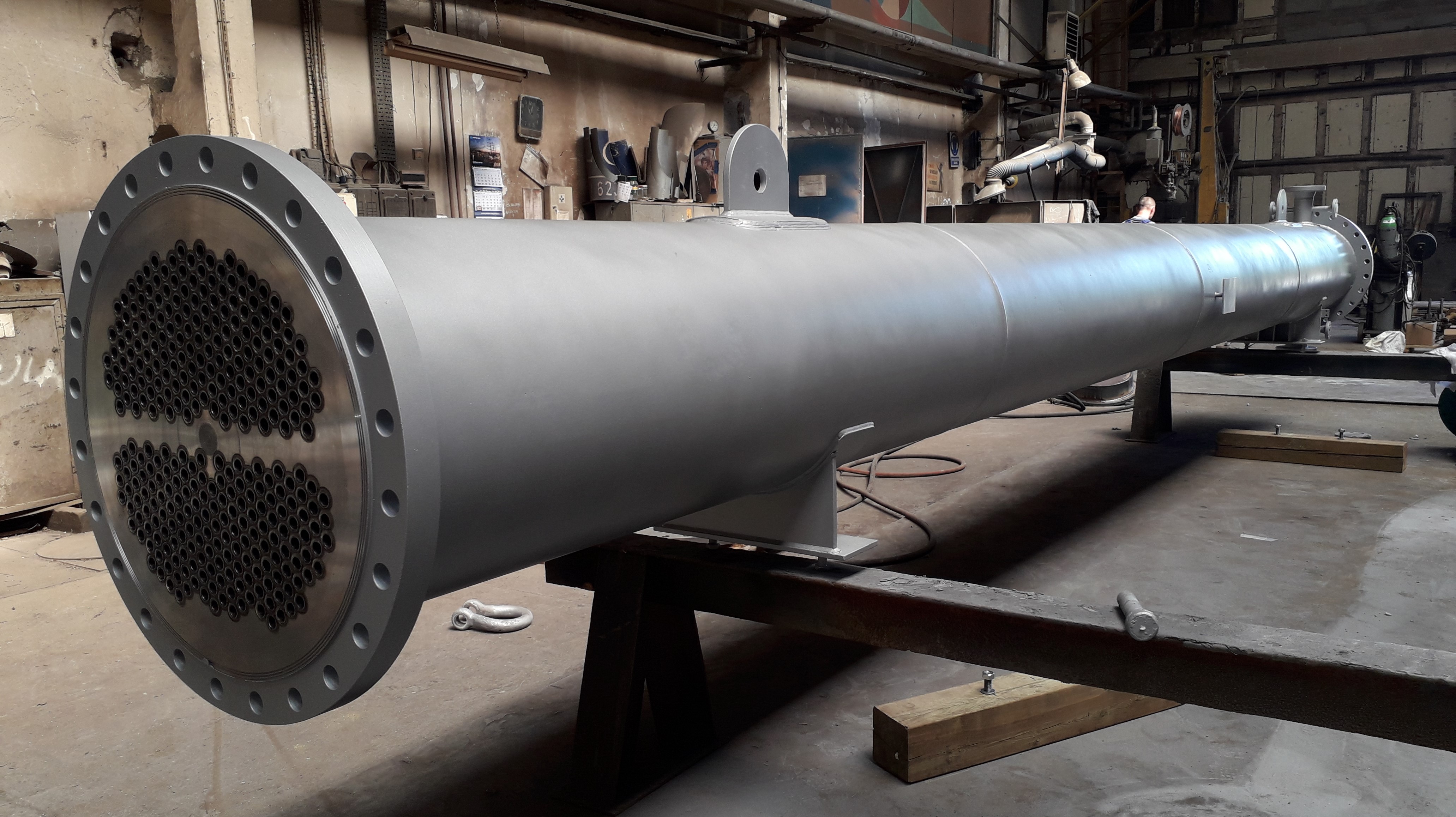

Tube bundle for refinery

Cooling medium: Water

Medium on the shell side: Hydrocarbons + hydrogen

Heat exchange surface: 295 m2

Used material: copper tubes

Project temperatures: -29 oC / 120 oC

Test pressure: 58,5 bar

Capacity: 3450 l

Total length: 6593 mm

.

Wymiennik dla Rafinerii

Medium: HP-DEC3

Heat exchange surface: 165 m2

Lenght of tubes: 7981 mm

Project temperatures: -10 oC/ +95oC

Test pressure: 27,2 bar

Capacity: 1860 l

Total length: 9360 mm

Heat exchangers for paint industry

.

Hydraulic oil water heat exchanger for paint production plants

Hydraulic oil / water heat exchangers capacities: 105kW/255kW

Heat exchange surface: 10,5 m2 / 17,5 m2

Max oil temperature: 100 oC

Max oil pressure: 25 bar

.

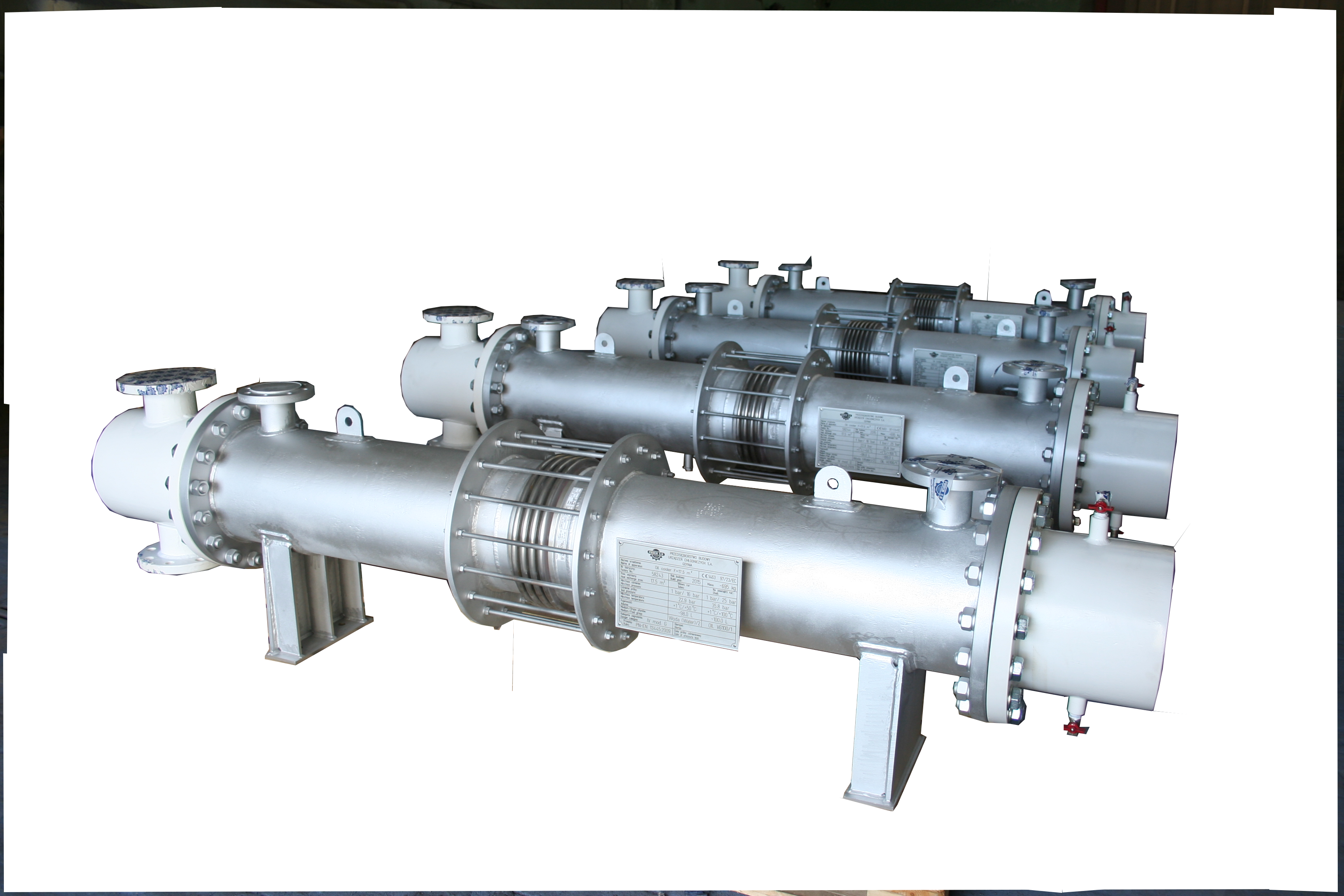

Oil heat exchanger 710 kW

Shell and tube heat exchangers for cooling oil

Material on the oil side: steel P265GH

Material on the water side: stainless steel SS304L

Exchangers are equipped with thermal expansions compensator

Processing equipment for power plant

.

Steam boiler

Main elements of a steam boiler are: pressure part with smoke tube and attaching stub pipes, input/output emissions chamber, exhaust gas recycle chamber with inspection doors on which the blower system of smoke tubes is mounted and the middle casing with protective plates.

Technical parameters:

Working pressure: 35 bar

Working temperature: 244 oC

Max vapor output: 13,2t/h

Heating surface: 1096 m2

Dimensions: 3935 mm x 4015 mm x 9103 mm

Designated for continuous work in industrial conditions (8000 h / year).

Certification according to EU directive 2014/68/EU in category IV mod. G

.

Vapour superheater

Main components of vapor superheater are coil pipes made of material 10CrMo910 and 13CrMo45 in two rows , supporting structure and housing.

The device includes following components: foundation with covers. ash hopper with isolation and inspection doors, main body with isolation and cover plates, exhaust head with inspection doors and chamotte consoles.

Parameters:

Working pressure: 35 bar

Working temperature: 500 °C

Dimensions: 4980 mm x 3885 mm x 11450 mm

.

Condensate heater

Main components of the condensate heater are coil pipe made of material P235GH, supporting structure, and housing

Unit is made of following components: base, ash hopper with isolation and inspection doors, main body with isolation and covering plates, exhaust head

Parameters:

Working pressure: 40 bar

Working temperature: 244 °C

Dimensions: 3785 mm x 3370 mm x 10050 mm

.

Boiler water tank

Parameters:

Material: carbon steel S235JR

Working pressure: 0,5 bar

Working temperature: 110°C

Dimensions: 1975 mm x 2565 mm x 5345 mm

Heat exchangers for petrochemical industry

.

Reboiler of oil stabilization

Shells of heat exchangers were made of steel, which fulfills requirements of NACE MR0175 and ISO15156 standard

One the tubes side flows thermal oil, on the shell side – crude oil

Tube bundle is made of tubes of steel P275NL1 working under increased pressure with adequate impact resistance for lowered temperature working conditions

Input heat exchange surface: 31,2 m2

Maximum pressure: 20 bar

Temperatures: minimal -29oC / maximal +200oC

Capacity: input 101 l, Shell 1390 l

The special requirement was anti-corrosion surface because preparing to coating and whole painting process was made under strict examination of FROSIO inspectors.

.

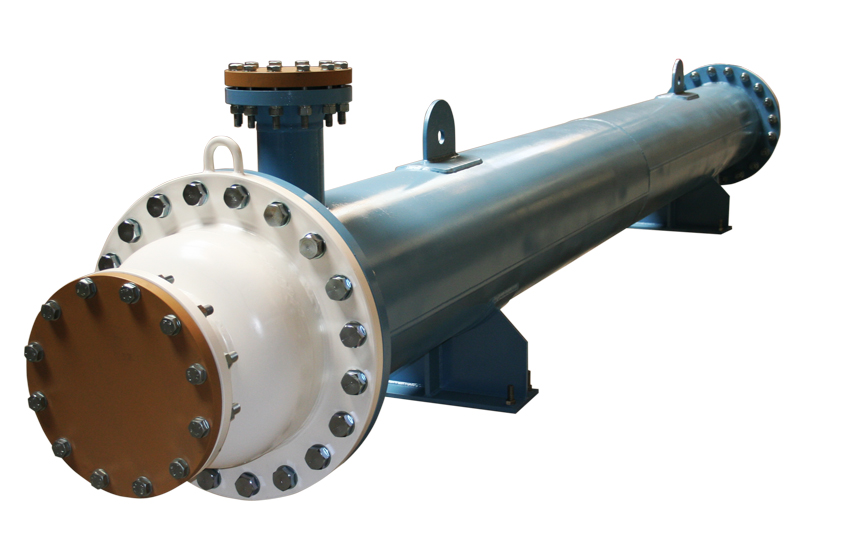

Oil vapor heaters

Shell and tube heat exchanger with replaceable tube bundle BEU type.

Inside the tubes flows heating medium – low-pressure vapor, which heats oil feeding desalting assembly.

Material of the shell: steel A-333 GR6

Tubes material: A-179

Perforated bottom material: A516 GR70

Design pressure: 17,25 bar

Min/max temperatures: -29/175°C

Dimensions: ø323,9 x 3000 mm

Tubes dimensions: ø19,05x2,11

Tubes amount: 38 pcs.

Certification: PED

.

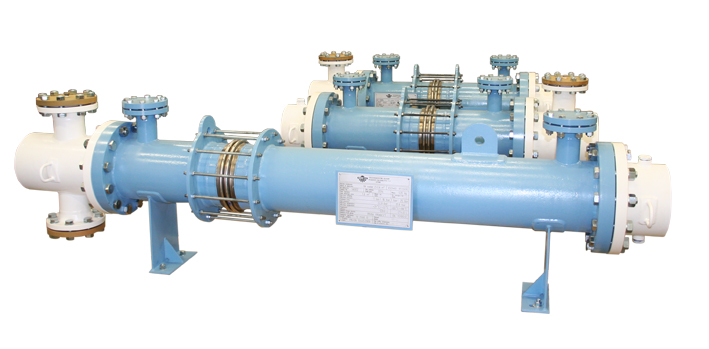

Reservoir fluid heater for oil and gas mine Radoszyn

Shell and tube heat exchanger with removable tube bundle, type AEU

Test pressure on the tube side: 228,9 bar,

Test pressure on the shell side: 22,9 bar

Min/max temperatures: -29/100°C

.

Storage tank for crude oil

Tank designed for crude oil storage

It was made as a 2-shell tank to provide protection against leakage.

Material: P265GH

Dimensions: ø1300x10

Min/max temperature: 0°C/50°C

Test pressure: 4,3 bar

Shell capacity: 35000 l

Certification: PED

Propylen subcooler and oil cooler

.

Propylen subcooler

Heat exchanger has been made by PBUCH SA commissioned by Aerzen Hungária Kft. for need of Zakłady Azotowe. Order also included preparing project of the heat exchanger, acceptance documentation and PRS/CE certification according to EU directive 2014/68/EU

Heat exchange surface: 160,7 m2

Project parameters:

Cooling capacity: 0,5 MW

Water capacity (inside tubes) – 468 dm3

Capacity of space filled with liquid propylene (inside the shell): 876 dm3

Diameter: 550 mm

Length: 7000 mm

.

Oil coolers

Calculation according to 97/23/EU

Working medium: water/oil

Max/min acceptable pressure: 16 / 25 bar

Pressure of hydraulic test: 22,9 / 35,8 bar

Max/min acceptable water temperature: +29,5/+27 oC

Max/min acceptable oil temperature: +75/60 oC

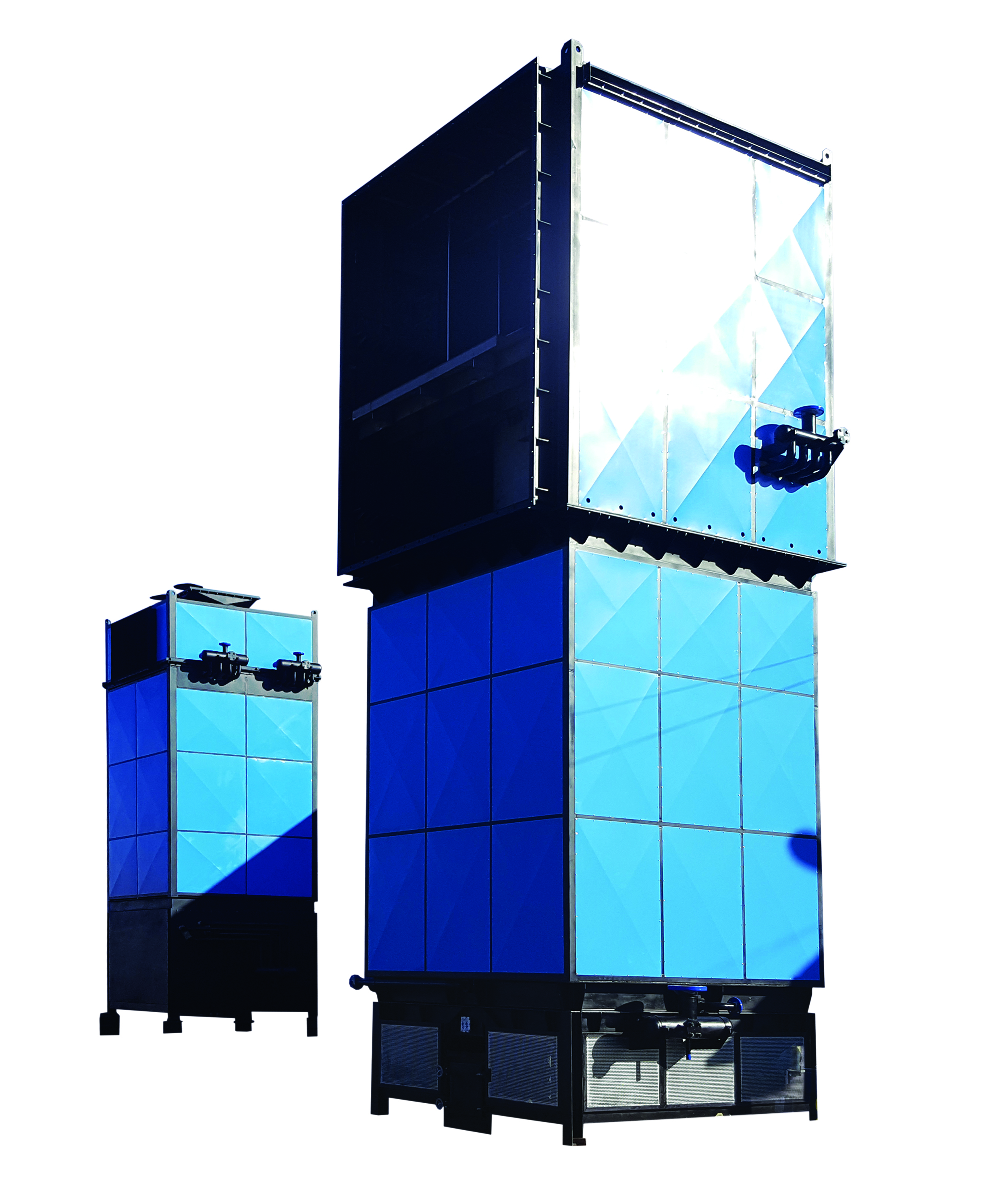

Water coolers for air for hydroelectric power plant

.

Coolers for ZRE Gdańsk

Heat exchangers designed for generators cooling system in hydroelectric power plant were buil on base of copper tubes packets with aluminium fins rolled in perforated bottoms made of galvanized steel P355GH. Covers were made according to our design as cast steel.

Processing equipment for Zakłady Azotowe

.

Tanks of ammonium sulphate solution and urea

PBUCH SA has manufactured and delivered pressure tanks for solid fertilizer manufacturing facility based on ammonium sulphate and urea. Tanks were assembled in manufacturing-distribution complex of solid fertilizers.

Material of tank: acid resistant steel in grade 1,4571 (316Ti)

Working medium: 28-40% ammonium sulphate solution

Pressure of air leaktightness test: 2,0 bar

Working temperature: +20oC to +90oC

Volume: 33,5 m3 and 10,5 m3

Weight of empty tanks: 4300 kg and 1950 kg

.

Sulpharic acid tank

Tank made of P265GH steel equipped with service platform

Working medium: Sulpharic acid 94-98%

Max pressure: 0,5 bar

Test pressure: 0,7 bar

Working temperature: -20oC to +60oC

Capacity: 34 000 l

Empty tank weight: 5750 kg

Engine room housings - DAMEN Marine Components

.

Engine room housings for Palfinger Dreggen

Execution of steel constructions of the engine room of specialized cranes for the off-shore segment.

High standard of finish and surface protection in accordance with NORSOK M501.

Total weight:15 tons

Poziome oddzielacze cieczy

.

POC

Oferujemy projekt, zatwierdzenie, produkcję, odbiór i certyfikację oddzielaczy cieczy do systemów chłodniczych na NH3, CO2 i do instalacji freonowych.

Maksymalne dopuszczalne ciśnienie: 25 bar

Max/min dopuszczalna temperatura: +50oC / -50oC

Dyrektywa ciśnieniowa: 97/23/EC

Przepisy: PN - EN 13445:2009